Ever more resource hungry, the UK’s built environment is the largest materials-consumer and waste-generator in the economy, accounting for 50% of all materials used and 60% of waste. The impact of this continuous process of material extraction and disposal on the health of the natural environment is hard to overstate. As designers operating within this context, we have become increasingly aware of and literate in the measurement of carbon on our projects, but efforts to reduce the use of raw materials are lagging behind. Finding fresh and innovative ways to reduce our dependence on material extraction will be key for a transition towards a circular economy.

As architects and technology specialists we have an opportunity to strengthen our understanding of material supply chains and embed circularity in the design process. An essential ingredient is a robust information management process to enable informed decisions on material analysis and reuse. Material passports have the potential to provide this framework and in turn, support the wider conversation on whole life carbon management.

Material passports record the characteristics of building materials and components and assign a value for their present use, recovery and reuse.

research parameters

The Allies and Morrison Design Technology team has been working on a proof of concept study to explore the use of Building Information Modelling (BIM) in centralising and organising material passport data. Our research focused on the complexity of information management on large scale commercial projects and the role we could play in transforming the industry from a linear ‘cradle to grave’ mentality to a circular model.

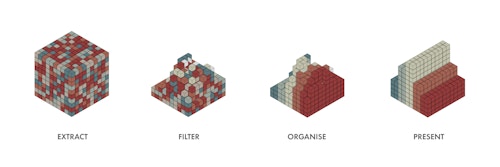

The research aimed to produce an interactive platform that could organise and interrogate building component data as an important first step towards our goal to embed circularity in building design through the reuse of reclaimed materials.

Through the exploration of supply chain capabilities, technology solutions and data management strategies, a core focus was to deliver this strategy across all project stages. Our approach had to be flexible enough to accommodate a breadth of skills across the industry and ensure that data quality remained transparent. Using existing industry standards such as the ISO19650 framework and COBie data schemas, we aimed to repurpose the project BIM information to become a digital inventory of assets for each project.

technology + data collection

Whilst BIM played a key role in organising material quantity data, it became clear that a database approach would be required if Environmental Product Declaration (EPD), deconstruction, material storage and transportation-related data were to be integrated. The feasibility of collecting data across all project disciplines and work stages was explored using existing industry data schemas such as COBie. The benefit of this was in providing a familiar framework for all contributors to structure their information and export the data in a consistent format. Establishing a unique identifier framework with an asset-specific code has been essential to move the model forward in any implementable way; enabling collation of data input from multiple contributors against each reuse asset.

Due to technology's ever-evolving nature, the platforms used had to remain flexible and adaptable; rather than building around a single software solution we developed a network of interchangeable tools. For a typical asset resume to remain useful over the long-term an interchangeable approach to technology was crucial, with a focus on embedding common exchanging formats such as .IFC schemas.

Using simple user interface development tools such as Microsoft Power Apps, complex datasets are distilled into an intuitive user interface. Basic information on asset identifiers and dimensions is displayed on the generated material passport, allowing the user to delve further into material performance and constitute data.

Material passport digital platform developed in collaboration with Great Portland Estates (GPE) on an innovative commercial office building project in the City of London.

What would be possible if the industry re-assessed the value proposition of BIM and data collection across the building's lifecycle?

We are confident that material passports can act as a stimulant for an industry slow to transition towards a circular future by establishing more data transparency across WLC stages A1 to D. While our research shines a light on the challenges that exist in maintaining such large datasets, we are excited to explore the opportunities emerging around blockchain, digital twins and AI. Could these technologies hold the key to the automation of vast, distributed material networks, where the buildings we deliver are embedded in global reuse material supply chains? For our industry to reduce its impact on the climate emergency, rapid acceleration is needed towards our collective efforts to explore the answer to that question.